General Industrial Adhesives

Polymer Science focuses on adhesives, tapes and coating solutions for companies of all sizes. Since our inception, we have artfully engineered highly specialized adhesives for aerospace, automotive, consumer electronics, electric vehicles and medical industries. Our adhesive products are far broader than these industries and span many general purpose applications. Companies who contact Polymer Science quickly discover our staff is responsive, knowledgeable and focused on creating the best solution to suit your application.

General Industrial Adhesives

One of the most popular general industrial adhesives designed by Polymer Science are our economical and high-quality heat-activated adhesives. Our Hybrid Acrylic-Rubber Heat Activated Adhesive bonds well to many surfaces including low-energy surfaces. Generally, rubber-based adhesives perform well on low surface energy materials but do not have the cohesive strength and stability of acrylic materials. Acrylic adhesives typically do not bond well to low surface energy substrates. Our experience working with many adhesives and polymers helps lead to innovations like our hybrid acrylic-rubber adhesives.

Heat-activated Adhesives

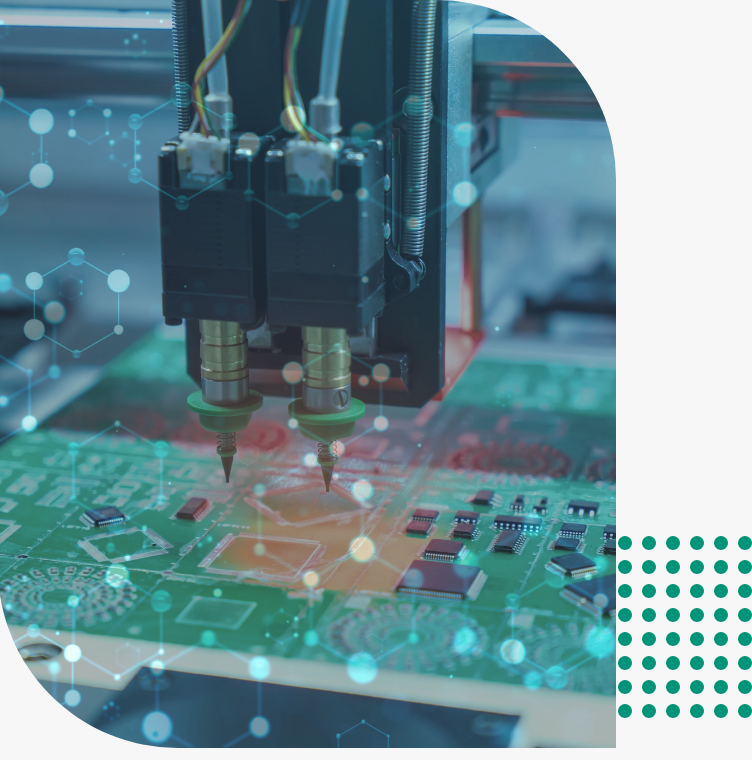

Heat-activated adhesives are one of the most convenient methods of bonding two or more substrates. There are three reasons heat-active adhesives offer practical solutions for many industries: ease of handling, strength of bond and flexibility.

Handling – These adhesives can be handled easily with no tack at room temperature. The adhesives can be added to many backings including cloth, films, foams, foils and papers. These materials can be fitted into tight corners and across multiple substrates.

Strength – As the name implies, the adhesives begin to bond only when a specific heat is applied. Once heated, the bond forms. As the adhesive cools, the bond is strengthened by crystallization. Over time, heat-activated adhesives resist aging, weathering, temperatures and shocks.

Flexibility – When at room temperature, the adhesives can be formed, fitted and even cut to exact specifications. The profile can be designed to suit a range of substrates including plastics, rubber, wood and metals. Our hybrid acrylic rubber adhesives offer even greater flexibility than acrylic adhesives.

Pressure-sensitive Adhesives

Pressure-sensitive adhesives (PSA) activate under pressure like general purpose tapes. PSAs may be applied to carriers like film tape or cloth tape. Like heat-activated adhesives, our pressure-sensitive adhesives bond many materials as a bilaminate or trilaminate. Generally, PSAs provide flexibility and perform well for many applications.

How to Contact Polymer Science

From delicate applications to the most extreme environments, Polymer Science provides responsive support to your inquiry. Whether you know the exact specifications of your materials or need assistance researching and developing an adhesive, our staff is eager to help. Since many of our materials are manufactured in the USA, we are able to provide adhesives promptly, even customized solutions.

General Industrial Products

Polymer Science designs, engineers and manufactures many materials for general purpose uses. Many of our adhesives, films, foams, tapes and coatings are effective for sealing and structurally bonding. These products include release liners, transfer adhesives, double coated and singled coated PSA tapes, heat-activated adhesives and non-adhesive materials. Many customers reach out to Polymer Science regarding materials from our P-DERM®, P-SHIELD® and P-THERM® product line. Our team works diligently to respond to all requests whether your interest directly relates to our catalog of products sheets or you need a customized solution.