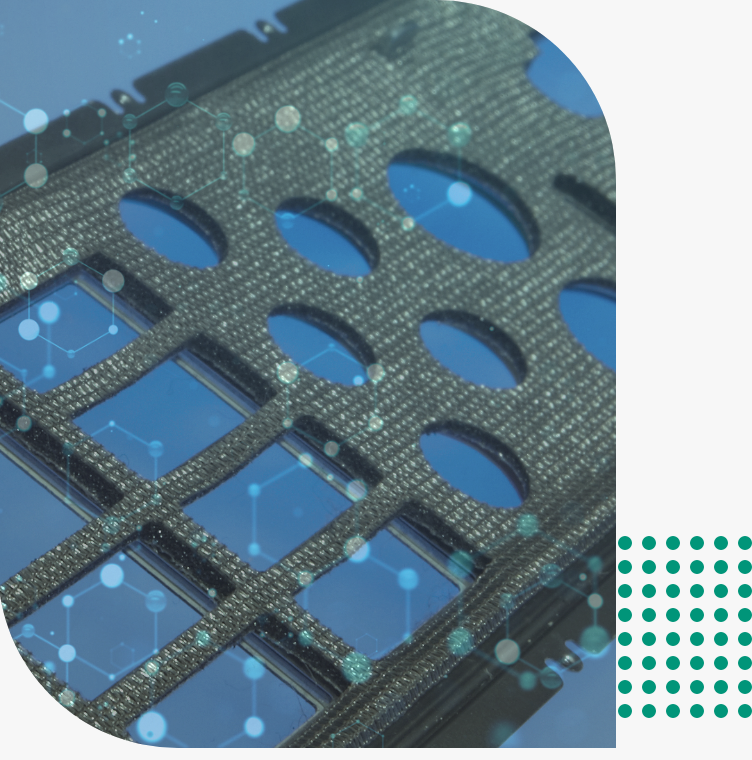

P-SHIELD® Conductive Foam without Adhesive

Conductive foams are used widely throughout electronic devices. Polymer Science’s P-SHIELD® foams manage electromagnetic interference (EMI) and supply a path for electrical current grounding. Many applications and emerging technologies benefit from our foams to fill gaps, absorb shock and conform within housings.

Conductive foams are conformable and compressible. P-SHIELD® conductive foam provides excellent EMI shielding and grounding properties from a thin and lightweight material. Primarily used to fill gaps and provide shock absorption within device housings, our components are available for fabric over foam gasket materials. Polymer Science constructs a variety of conductive silicone foams, electrically conductive polyurethane foams and conductive polyolefin foams. Our experienced team can work quickly to identify the solution to suit your requirements.

EMI Shielding and grounding foam gaskets are used in electronic device housings to properly shield EMI noise from interfering with the performance of the device. Most elastomers including silicones, polyurethanes and polyolefin are natural electrical insulators. Polymer Science improves the conductivity of these materials by plating with nickel and copper metal. They may also be supplied a a multilaminate with a conductive foil for enhanced shielding performance. P-SHIELD® conductive foams are robust, durable and ideal for converting in many industries including electric vehicles (EV), smartphones, tablets, wearable devices, smart appliances, tablets and more.

Conductive foam serves multiple functions within electronic devices. Wherever there is a need to control electrical interference, P-SHIELD® foam materials deliver low compression and high conductivity in X, Y and Z axes. Conductive foam also acts as a shock absorber and tolerates heat. Without adhesives, conductive foams benefit a number of manufacturing processes as they are easy to handle and repositionable. With a wide range of compression force profiles ranging from soft to more rigid, our foams compress to fill gaps between delicate components and device housings. When you contact Polymer Science, our team responds quickly to identify and deliver the right product.

P-SHIELD® Conductive Foam without Adhesive

Computers

As computers become more compact, conductive foam tapes and foams solve multiple functions in a single material. P-SHIELD® conductive foam shields EMI, fills gaps while conforming to components and absorbs vibrations.

Smartphones

Polymer Science’s P-SHIELD® foams provide effective shielding, help absorb shocks and provide some moisture protection in mobile devices. Non-adhesive foams can be cut to shape and provide noise filtering in smartphones.

Tablets

Conductive foams are used alongside other Polymer Science materials including thermal management materials, fabric tapes, films and foil tapes. Beyond providing shielding, conductive foams conform to fill cavities, filter noise, absorb shock and offer a water seal.

Navigation & Infotainment Systems

One of the most common uses for conductive foams is filling gaps within device housings. The systems within electric vehicles, general automotive and other interactive devices require EMI shielding and grounding. GPS navigation devices, infotainment and other displays feature delicate components. Foams help protect these components, control noise and reduce overall weight.

Medical Instruments

Polymer Science designs and engineers a wide range of medical tapes and adhesives for skin contact. Medical settings demand efficient shielding. Our P-SHIELD® foam tapes with PSA and foams without adhesives are used in medical instruments to shield, insulate and fill gaps within device housings.

Smart Appliances

Conductive foams fill gaps and offer shielding and grounding within smart appliances. Single-coated foams offer a solution that is lightweight and economical.

Polymer Science P-SHIELD®