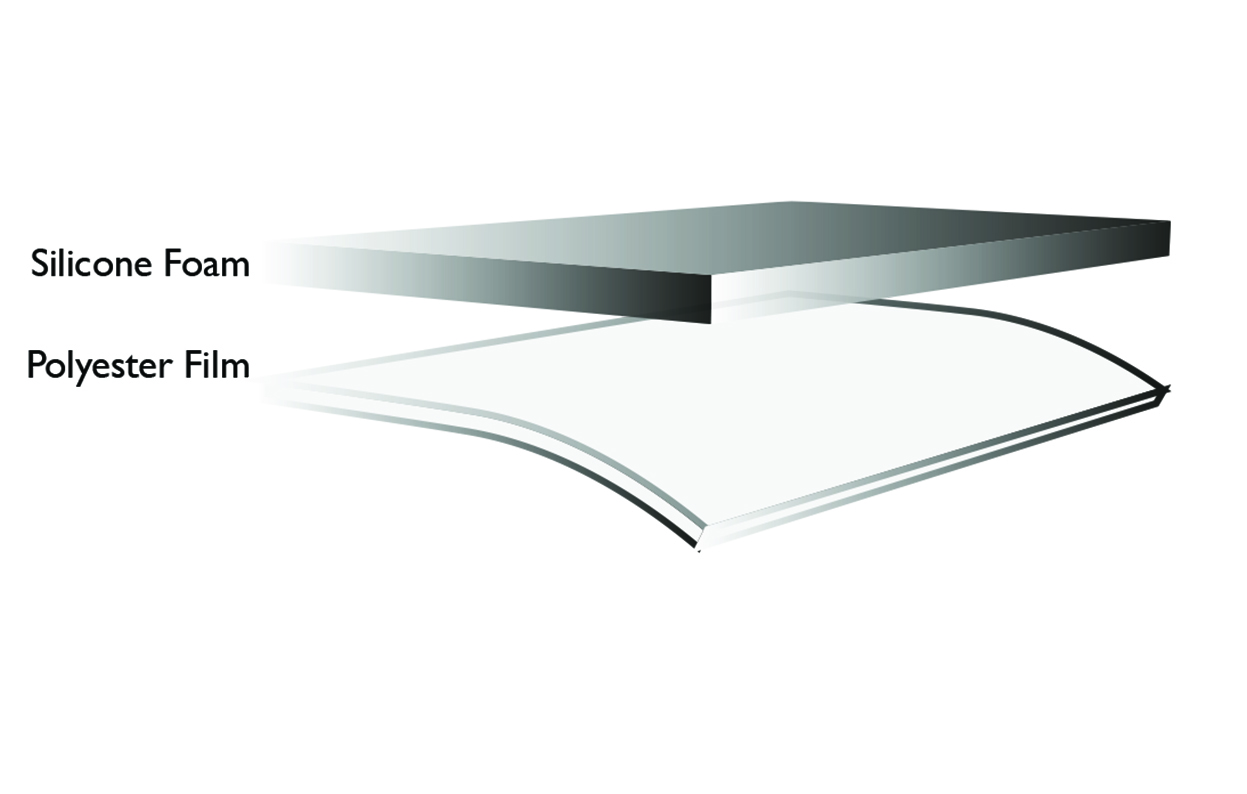

PS-2924-xxTBL is a soft nonconductive silicone foam used for sealing and shock absorption in automotive,

aerospace, consumer electronics and industrial applications. PS-2924-xxTBL is supplied with a removable

polyester carrier for added support during die cutting and handling.

General Industrial

PS-2924-xxTBL

Good Resistance to Compression Set

Good Chemical Resistance

Highly Elastic

Flame Retardant

RoHS and HF Compliant

Good Chemical Resistance

Highly Elastic

Flame Retardant

RoHS and HF Compliant

| Property | Value | Test Method | ||

|---|---|---|---|---|

| Thickness(mm) | 1.59 - 12.7 | QSP-726 | ||

| Color | Black | -- | ||

| Polyester Thickness (mm) | 0.057±0.03 | QSP-726 | ||

| Hardness (Shore 00) | 34 | ASTM D2240 | ||

| Density (kg/m3) | 275±40 | ASTM D1056 | ||

| Water Absorption (72 hour submerssion) | 48% | -- | ||

| Tensile Strength (kPa) | 3.18mm | >3.18mm≤7mm | >7mm | ASTM D412 |

| ≥180 | ≥150 | ≥140 | ||

| Elongation (%) | ≥100 | ASTM D1056 | ||

| Tear Strength (g/mm2) | 164 | ASTM D624 | ||

| Compression Set (%) | ≤5 at 100 C / ≤5 at 175 C | ASTM D1056 | ||

| Adhesion to SUS | >100 N/100mm | ASTM D3330 | ||

| Total Mass Loss (@125 C/24 hrs) | 0.48% | ASTM E595** | ||

| Flame Resistance | V0 | UL94 | ||

| Thermal Conductivity (W/m K) | 0.08 | ASTM C518 | ||

| Dielectric Breakdown Strength (kV/mm) | 4.7 | ASTM D412 | ||

| Volume Resistivity (Ω cm) | 1.73 x 1014 | ASTM D257 | ||

| Continuous Use Conditions | -55 - 200 C | QSP-754 |

**Tested at atmospheric pressure