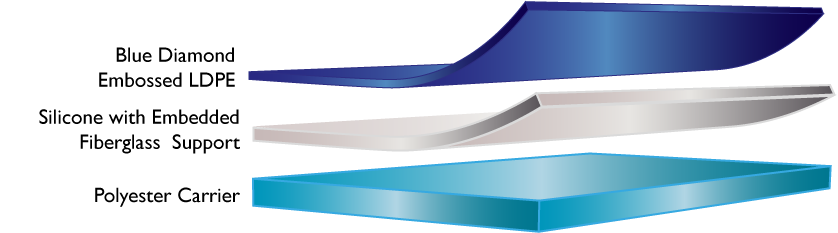

P-THERM® PS-2642 is a silicone based thermally conductive gap filler with an embedded fiberglass support and 125 micron removable polyester carrier.

P-THERM®

PS-2642

Good Thermal Conductivity

Excellent Compression Characteristics

Excellent Wet-Out

Superb Flexibility

Excellent Converting Properties

RoHS and HF Compliant

Excellent Compression Characteristics

Excellent Wet-Out

Superb Flexibility

Excellent Converting Properties

RoHS and HF Compliant

| Property | Value | Test Method |

|---|---|---|

| Flammability Rating | V-0 | UL 94 |

| Continuous Use Conditions | -60 - 200 C | QSP-754 |

| Hardness (Shore 00) | 47 | ASTM D2240 |

| Dielectric Breakdown Strength (kV/mm) | 20 | ASTM D149 |

| Thermal Conductivity | 2 W/m K | ASTM D5470* |

| Thickness Range | 0.5mm - 5.0mm | ASTM D374 |

| Reinforcement Carrier Type | Fiberglass | -- |

| Color | Blue | Visual |

| Density (g/cc) | 2.43 | ASTM D792 |

| Heat Capacity (J/g K) @ 50 C | 1.08 | ASTM E1269 |

| Total Mass Loss (@ 125 C/24 hrs) | 0.08% | ASTM E595** |

| Volume Resistivity (ohm-cm) | 1.0E + 11 | ASTM D257 |

| Thermal Impedance (K cm^2 /W) @ 1mm | 10% Strain: 5.45, 20% Strain: 5.18, 30% Strain: 4.91 | ASTM D5470*** |

* Thermal conductivity tested at 20% strain.

** Tested at atmospheric pressure

*** Values tested include interfacial thermal resistance: Application performance is directly related to surface roughness, flatness and pressure applied.

** Tested at atmospheric pressure

*** Values tested include interfacial thermal resistance: Application performance is directly related to surface roughness, flatness and pressure applied.