P-DERM® Custom Solutions Guide

For manufacturers and design engineers of medical devices, dressings and other skin contact applications, choosing an adhesive for skin contact is essential to success. Medical grade adhesives are required across many applications including dressings, wound care, scar therapy, wearable devices, and general medical tapes. For manufacturers, choosing the ideal medical grade adhesive improves the performance of their products from simple bandages and minor burn care to the most complex dressing such as negative pressure wound therapy and medical trauma.

Polymer Science has been an industry leader since 1998. Our team provides a wide range of skin adhesive solutions. Our experience, skill and U.S.-based manufacturing provide our partners with a versatile and reliable supplier.

P-DERM® Skin Contact Adhesive

In our Custom Coating Guide, we provide insight into our services, our capabilities, our products and a few of the markets we serve. Whether your company needs a simple medical tape for the securement of first aid dressings or advanced wound care where medical adhesives help promote healing and prevent infection of fragile skin, Polymer Science is eager to consult with you. We can identify the ideal formulation including silicone adhesives, hydrogels and conventional acrylic skin adhesives.

OUR SERVICES

Polymer Science is committed to providing you with today’s most innovative skin contact adhesives for the medical industry.

Our diverse team of highly skilled engineers and technical staff, in conjunction with our state-of-the-art equipment, provide you with a quality product that is consistent with your application requirements.

Our design team works quickly to provide the solutions you need, allowing your project to expeditiously move from conception to commercialization giving you the edge to ensure your next project is a success.

Defining the Project

In the initial stage of project development, our sales team will gather information to define the scope of the project, as well as the design criteria for your skin contact medical adhesive, coating or tape.

Design & Assess

Polymer Science has a wide range of medical grade adhesives, coatings and tapes that may meet your requirements. If necessary, you will work with our diverse team of engineers in developing and modifying the original solution to ensure you are provided the best product possible with product and manufacturing feasibility.

Verification & Validation

During the verification and validation stage, we will determine the reproducibility and repetition of the manufacturing process. This ensures your custom medical grade adhesives will consistently meet our standards and your needs.

Commercialization

At this stage, development is complete and the process is then transferred to our highly skilled sales and operations teams.

Aftermarket Support

With help from our technical services, engineering and quality teams, we will continue to work with you to ensure that our material continues to meet the form, fit and function demands necessary for the success of your product.

OUR CAPABILITIES

Custom Construction Solutions

Designing a product that meets every desired requirement can seem like a daunting task. When you partner with Polymer Science, our processes and structures provide a clear path to success. Choosing the right adhesive may seem tricky enough, but there are a wide variety of carrier and liner options available that will also give your product different characteristics.

Working with a supplier that understands the material characteristics and how they will impact your project will save you a lot of time in the research and development phase of your project. Polymer Science is dedicated to ensuring that you are not only using the correct medical grade adhesive for your project, but that the construction enhances your go-to-market finished project. We have the ability to offer many different construction types, as well as a perforation to single or multiple layers of your product.

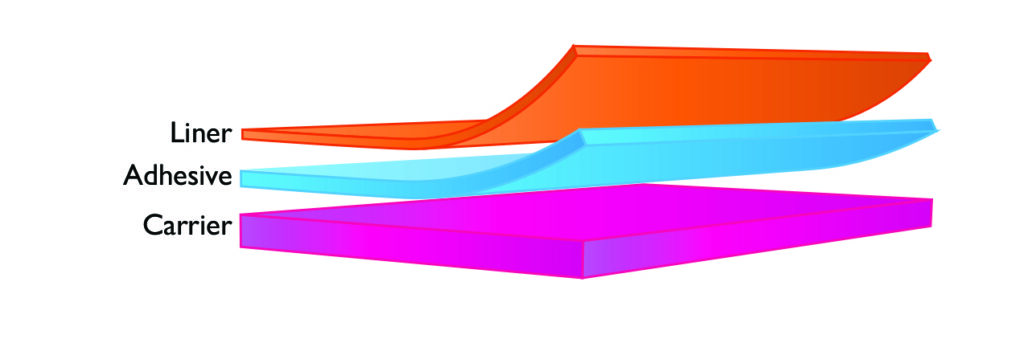

Single Coated

Our single coated construction consists of a single layer of adhesive with a carrier and a single liner. Our single coated materials can be supplied as transfer adhesives.

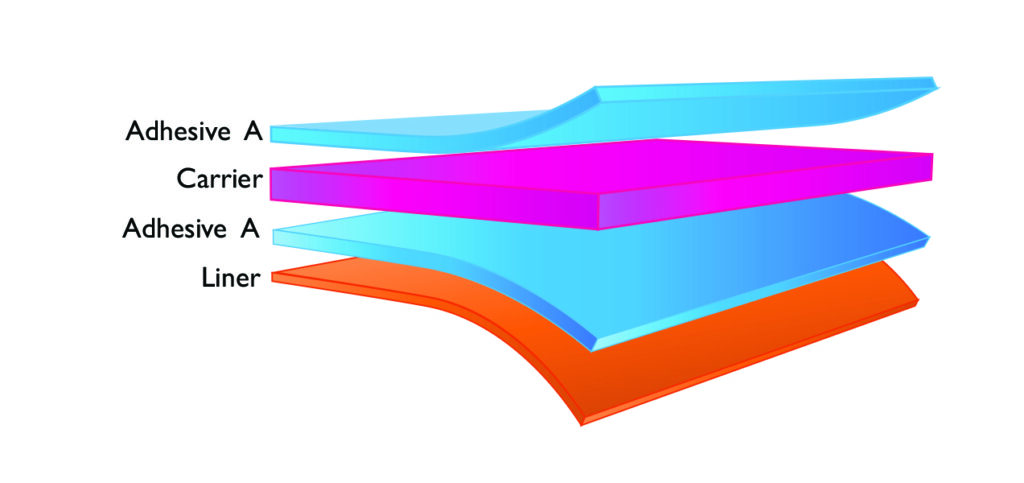

Double Coated

Our double coated construction consists of a single layer of the same adhesive on each side of a carrier. Standard construction is supplied with only one liner. Our double coated materials can be supplied with two liners as well.

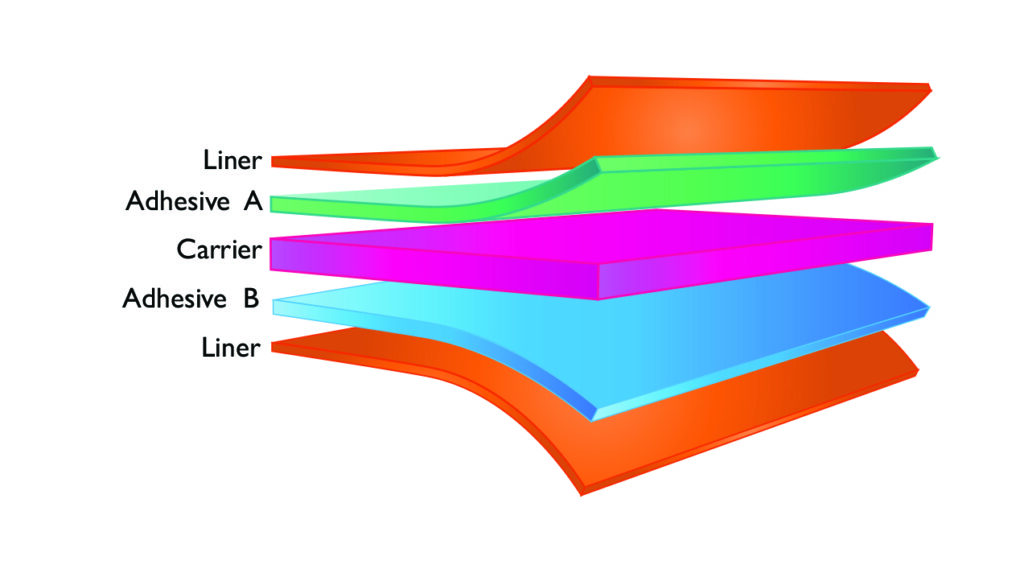

Trilaminate

Our trilaminate construction consists of a single layer of adhesive coated on one side of the carrier and another single layer of a different adhesive coated on the opposite side of the carrier. This construction is supplied with two liners.

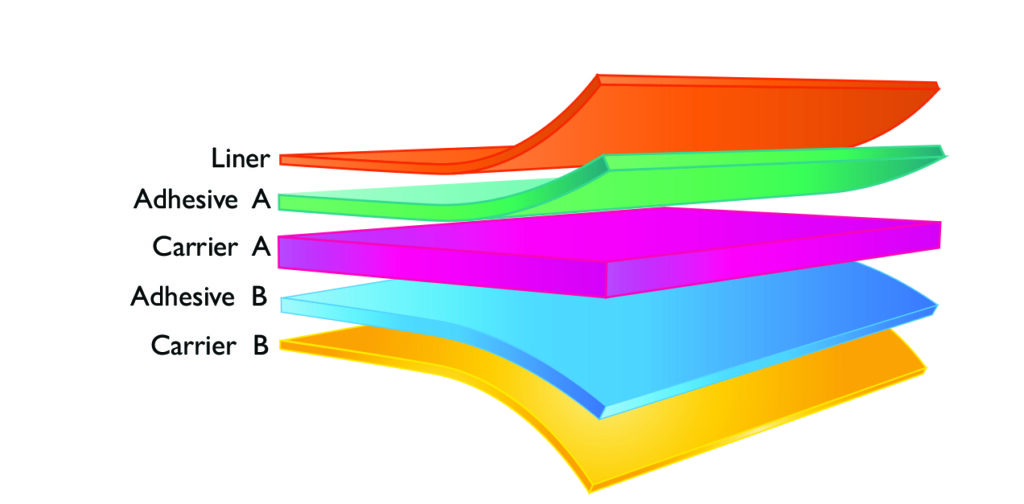

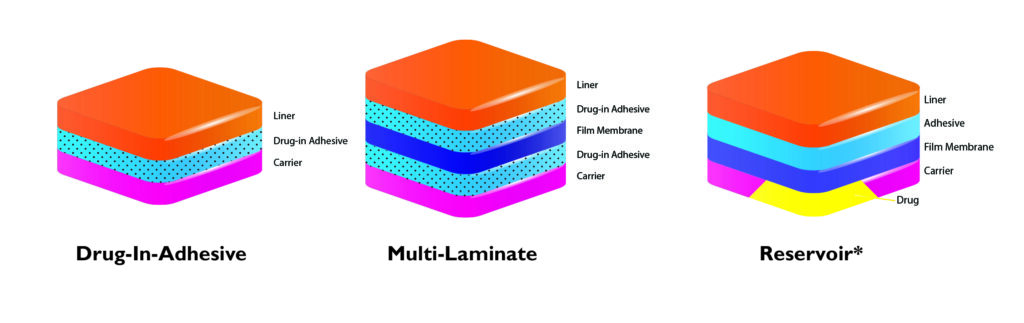

Multi Laminate

Our multi-laminate construction consists of infinite combinations of our adhesives, carriers and liners supplied on a single roll of product. Multi layer laminating ensures the ideal medical grade adhesives are utilized for skin contact, device fixation and all other needs within your project.

Coating Solutions

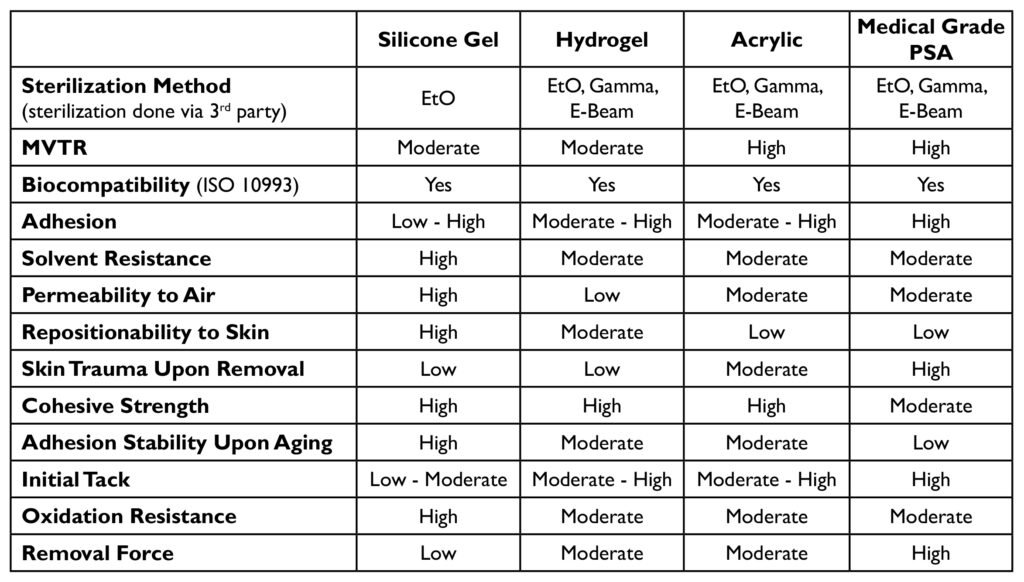

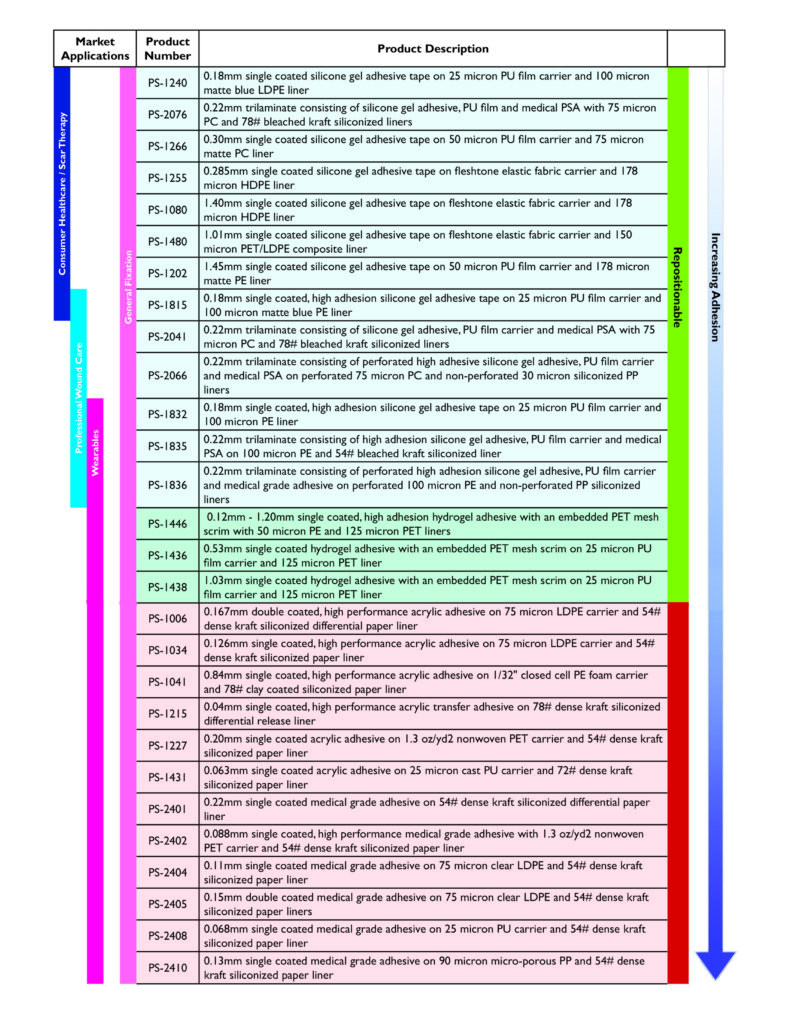

Polymer Science has been coating medical grade adhesives since 1998. We have extensive experience and knowledge coating silicone gel adhesives, hydrogel adhesives and medical grade PSAs (Pressure Sensitive Adhesive). Our experience extends from basic device securement and first-aid bandages to sensitive skin and skin trauma solutions. We are proud to state that all of our P-DERM® skin contact adhesives are made in the USA. This provides some distinct advantages within the supply chain for our partners.

Materials Available

Adhesive Systems: Silicone Gel, Hydrogel, Acrylic, Medical Grade Adhesives

Liners: Films (Polycarbonate, Polyester, Polypropylene, Polyethylene, Polypropylene, Fluorosilicone Polyester, Fluorocarbon Polyester) and Siliconized Paper (Dense Kraft, Bleached Kraft, Clay Coated)

Carriers: Polyurethane, Polyethylene, Polyethylene Foam, Nonwoven Polyester, Nonwoven Polyurethane, Elastic Fabric, Micro-porous Polypropylene

Coating Capabilities

Polymer Science is a roll-to-roll manufacturer of skin contact adhesives. We have the ability to produce our rolls in various widths, lengths and constructions. Polymer Science also has Corona Treatment technology for surface energy modification when necessary for your medical adhesive.

Widths:

Up to 750mm

Construction Types:

Single Coated, Double Coated, Trilaminate, Multi-Laminate

Coat Weights:

Silicone Gel Adhesives — 25 gsm – 1400 gsm

Acrylic Adhesives — 20 gsm – 200 gsm

Hydrogel Adhesives — 120 gsm – 2000 gsm

Medical Grade Adhesives — 20 gsm – 250 gsm

Coating Techniques:

Knife over Roll

Slot Die

Reverse Roll

Gravure

Hybrid Technologies

Pattern/Zone

Calendar

Comma

Curing Techniques:

Thermal

Infrared

Ultraviolet

Converting

Polymer Science has the ability to perforate, slit and laminate roll stock materials. We have a wide range of trusted converting partners who have the capabilities to slit, print, laminate, die cut, laser cut, assemble, seal and package your product. We would be happy to recommend one of our converting partners to you.

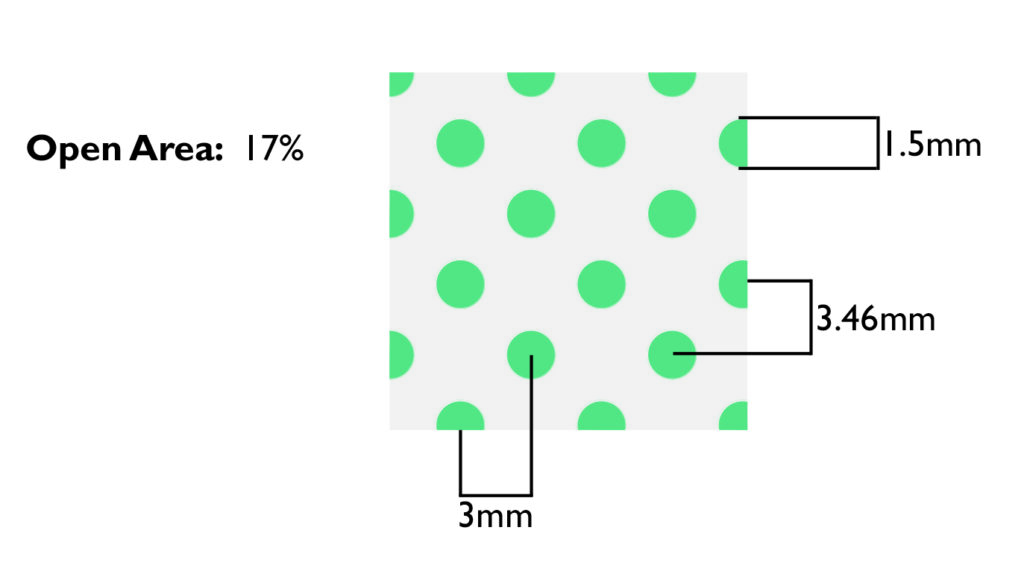

Perforation Capabilities

We can perforate all of our P-DERM® skin contact adhesive products. Our flexibility allows us to perforate one or multiple layers of your construction. We have our standard perforation pattern available or we can create a custom pattern specific to your application. Our perforated products boast the highest quality, providing clean and consistent holes throughout.

Additive Loading Capabilities and Constructions

Transdermal drug delivery patches provide patients with a pain-free, convenient delivery method of an active pharmaceutical or cosmeceutical ingredient. Selecting the correct components and constructions for these systems is critical. Polymer Science will work with you from start to finish, developing the highest quality medical grade adhesive available. All of our additives are compounded on-site.

Types of Additives Available: Antimicrobials, Cosmeceuticals, Pharmaceutical Actives

* Polymer Science can supply the liner, adhesive and film membrane for the reservoir construction. The carrier and drug will need to be added by a converter.

Our Products

Adhesive Characteristics

Our Markets

Advanced Wound Care

Advanced wound care products are designed to cure and treat complex wounds. Advanced wound management provides moisture to the wound site to allow cells to heal and repair naturally. Highly exudative wounds like diabetic ulcers and surgical wounds benefit from a range of acrylic and silicone adhesive, as well as non-adhesive skin contact materials.

Applications:

Antimicrobial Dressings

Traditional Foam Border Dressings

Negative Pressure Wound Therapy Dressings

Incise Drapes

Surgical and Wound Closure Tapes

Pressure Ulcer / Pressure Injury Dressings

Minor Burn Care Dressings

Consumer Healthcare

Consumer healthcare products mainly consist of over-the-counter (OTC) drugs, dressings and other specialty products that can include medicines, which are sold directly to a consumer without a prescription from a healthcare professional. Patients rely on medical adhesives for first-aid bandages and other common skin applications.

Choosing a suitable adhesive must consider sensitive skin, adhesive residue, skin movement and many other factors. The difference between a best seller and a failure comes down to smart decisions in the design process. Polymer Science offers decades of experience in medical tape, coatings and adhesives to benefit your project.

Applications:

Bandages

First Aid Dressings

Minor Burn Care

Blister Prevention

Fashion Adhesives

Scar Therapy

Wearable Devices

Wearable devices are non-invasive, body-worn devices that are attached by a skin contact adhesive and often include a device capable of tracking information related to health and fitness. Both medical devices and general-purpose wearable equipment must understand the needs of the patient’s skin and their usage.

Applications:

Continuous Glucose Monitoring (CGM)

Vital Sign Monitoring Devices

Pulse Oximetry

Telemetric Monitoring

EEG

Fetal Monitoring

Thermometer and Fever

Activity and Fitness Monitoring

Sweat Analysis

Sleep Analysis

UV Exposure

Athlete Contact/Force Analysis

Step and Calorie Tracking

Ostomy & Incontinence Care

Ostomy and incontinence care take place following a bowel or bladder diversion surgery creating a stoma. The stoma drains into a pouching system attached by an adhesive creating a secure seal, as well as, a barrier protecting the skin around the stoma. Medical grade adhesive for skin contact in this application benefits from hypoallergenic and atraumatic removal.

Applications:

Ostomy Flanges

Ostomy Extenders

Incontinence Gaskets

Incontinence Seals

Transdermal Drug Delivery

A transdermal drug delivery patch is a medicated adhesive patch that is placed on the skin to deliver a specific dose of medication or vitamins through the skin and into the bloodstream. This skin adhesive must provide reliable adhesion and easy removal for patients.

Applications:

Cosmeceutical Patches

Under Eye Patches

OTC Therapeutic Patches

Wart Remover Patches

In Vitro Diagnostics

In vitro diagnostics are tests done on samples such as blood or tissue that have been taken from the body. IVD can detect diseases or other health conditions and can be used to monitor a person’s overall health to help cure, treat, or prevent diseases.

Polymer Science offers hydrophilic coatings in the IVD market, as well as clean adhesives that do not interfere with the delicate chemistries within in vitro diagnostic testing applications.

General Fixation

General fixation tapes are adhesive-backed paper, cloth, latex, foam, mesh, or other material used to secure wound dressings or other medical devices to the body.

Applications:

IV Securement

Medical Tapes

Surgical Tapes

Catheter Placement

Post-Op Dressings

Our Standards

Compliance and Quality

It is our goal to provide the highest quality products for your medical grade application by ensuring our manufacturing processes meet the range of regulatory boundaries that your products touch.

We have integrated a total quality management system into each and every product that we manufacture. Polymer Science is registered to ISO 9001:2015 and ISO 13485:2016. We also comply with ISO 10993 (ISO 10993-10, ISO 10993-5, and ISO 10993-1) regarding skin sensitization and irritation. Our registrar is an internationally recognized BSI.

Quality standards are audited internally and by a 3rd party registrar to ensure that each product is manufactured with our customers’ regulatory requirements in mind. We are cGMP compliant and registered with the FDA as a medical device and OTC drug manufacturer.

Materials Testing

In the Polymer Science testing lab, we perform a range of physical and mechanical tests on our materials to ensure they meet the form, fit and function requirements of your project specifications. Our biocompatibility testing is done via a third party. We do not perform analytical testing on our products but can have this completed via a third party when requested. This information is available on our technical data sheets or upon request.

Physical Testing

- Adhesion and Release

- Tensile Strength

- Shear

- Tack

- pH

- Coat Weight

- Viscosity

- Penetration

- Accelerated Aging

- Moisture Vapor Transmission

Rate (MVTR)

- Liquid Transmission Rate (LTR)

- Elongation

- Contact Angle

- ID Testing via FTIR and TGA

- Residual Solvent

- Thickness

- Durometer / Hardness

Biocompatibility Testing

- Irritation – Primary Dermal

- Sensitization – Buehler

- Cytotoxicity